What is it? Hint: your life depends on tools like these.

Some time ago we wrote about five relatively obscuretools for doing electronics. But, five tools barely scratches the surface of the stuff out there, and here are a few more of our favorites. In this roundup we’ve collected some handy–and even important –tools along that you might not have seen before, along with some best-of-breed versions of everyday electronics tools.

1. The Ideal “T-stripper,” model 45-121. I’ve used an awful lot of different wire strippers– even much more expensive ones –with different geometries, brands, mechanical principles, and levels of precision, but this is the one that I’d want on a desert island. It’s really that good.

It’s fast, solid, sharp, and durable. No nonsense. Precise. It works perfectly the first time, every time. The inner cutter part cuts through ridiculously thick wire and cable with ease. Handles are comfy and long lasting. Overall, it’s just hard to say enough good stuff about it.

If you have one of these, it’s easy to forget that there are so many simply terriblewire strippers out there. But then someday someone asks to borrow your wire strippers. You let them and then, after stripping their wires they stop and stare at for just a moment– surprised.

Here’s another version. It’s still the T-stripper, but it’s the bent-handle model– meh –and it’s also branded by Technitool. Still cuts freaking well. These are also available in smaller and larger wire-gauge sizes and in red or yellow handles to label whether they’re calibrated for solid or stranded wire.

2. “Surgical tools.” Soldering isn’t brain surgery. Only, sometimes it is.

Clockwise from top: Hobby knife, nonmagnetic fine point tweezers, scissors of different sizes, hemostats or locking forceps.

Hobby knife: No, this isn’t really a surgical tool. Scalpels are easy to come by, but I find that the blades are generally too thin. They flex and break. In most cases for electronics, the good old hobby knife is stronger and more capable. This tool is one of the most important for general-purpose repair and hacking. You can use it to easily cut a trace on a circuit board, to scrape the solder mask off of a trace, to trim down stubborn connectors, or to cut a path through a molten solder bridge. Just damn handy.

Fine point tweezers in different shapes: Just the thing for setting individual surface mount components in place. The angled ones make it much easer to flip over a component– say that tiny SMT resistor that happened to land upside down. They’re also handy for guiding wires into terminal blocks and placing patch wires before you solder them down.

Scissors: For trimming kapton tape to size, cutting copper wire in awkward locations, and fitting where wire clippers can’t. And for all kinds of other things you never think of until you use them.

Locking forceps: Like the grown up version of an alligator clip. Use it to hold two wires near their intersection for soldering, or any number of other uses. (See here for some of those other uses.)

3. The super chip squisher. More properly a (fancy) DIP IC lead forming tool.

The purpose of this type of tool is to bend the leads of DIP-ICs so that their wire leads point straight up and down, rather than out at an angle– making it easier to insert them into a circuit board or a socket.

In our earlier articlewe showed a simpler, handheld IC lead forming tool.

This one is different. It has a center guide that you slide the chip along. The chip then goes between two ball bearing rollers that uniformly compress the “shoulders” of the chip, crimping it just enough– simply by sliding it right through. The two screws on the top side can be loosened to adjust the spacing of the ball bearings if need be. The top side of this tool is for 0.3″ lead spacing DIP chips. The bottom side of this tool looks similar, but has a wider center guide that fits 0.6″ lead spacing chips.

4. The humble solder sucker, one of the basic desoldering tools. Melt the solder joint with your iron, bring the tip of this very close and push the button– quickly, without letting the solder cool. Push the spring-loaded piston back down to cock it for the next solder joint. Works moderately well, and quite inexpensive.

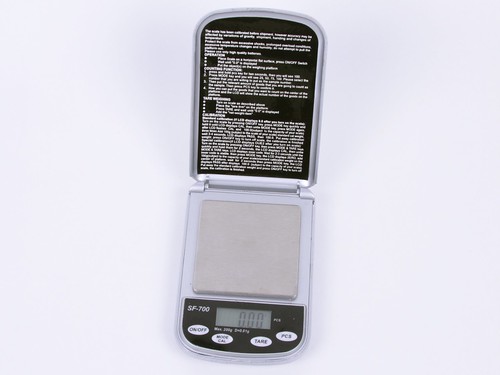

5. Counting scale. If you need to count out 193 resistors or 325 tiny screws for a project, a counting scale is a very helpful device. This one came from eBay and has a 200 g capacity with 0.01 g resolution; you’ll need high resolution like that if you want to accurately count tiny parts.

6. Lots of tiny screwdrivers. Now, I’m really not one to advocate interchangeable bit sets in general– real tools are better –but the simple fact is that there are *a lot* of little screw sizes out there. This particular set, the Boxer 30 piece, 4 mm “Precision Screwdriver Set” happens to be surprisingly nice.

Yes, it’s inexpensive, and the individual tips won’t last forever, but it’s damned handy and reasonably well made. The whole set costs about ten dollars. Includes metric hex sizes, phillips, torx, flathead, and very little else. I’ve used almost every tip in my set. (Er, sets. Get one for every desk that you work at.)

7. The cable tie gun, or “installation tool” more formally. What does it do? It tightens cable ties. No really! It’s pretty common in non-critical situations to just tighten cable ties by hand, or maybe with pliers, and then to just clip off the loose end. If that’s your system, it may be hard to understand why you’d want a specialized tool to do it for you.

The reason is simple: It’s just that sometimes– actually often –cable tie tension isabsolutely critical. Consider, for example, the wiring harnesses that make up the wiring on an aircraft. If the wiring is too loose or too tight, it will eventually be damaged by fatigue or damage to the insulation. One way to solve that is to use a tool that consistently tightens cable ties to a specific, dialed-in tension. This tool does just that: it lets you tighten a cable tie to an exactly set, very reproducible tension, and then cuts the loose end– usually in one swift motion.

(Note: this certainly isn’t the only way to make tough, reliable wiring harnesses. For example, cable lacing is a good alternative method.)

To use the tool, you first loop the cable tie together, and then insert the loose end into the muzzle of the tool. With a squeeze of the trigger, it takes out the slack, tightening towards your set tension.

Then, right when you reach the set tension, something very different happens:

Rather than applying additional pressure as you squeeze, instead a hidden knife bladecomes “out of nowhere” and cuts the cable tie, nearly flush, with the right tension. If you look closely in the picture above, you’ll see the knife blade starting to cut into the cable tie.

Once you get the hang of it, it’s incredibly quick– just a single good squeeze to take out slack, tension, and cut the cable tie.

It’s also amazingly strong, and can tighten cable ties to a much higher absolute tension than is usually possible otherwise. A consequence of this is that you always need to dial it down before using smaller thin or narrow ties– otherwise they just snap under the tension.

The particular tool shown here is Panduit model GS2B, and it’s stellar. At only 0.2 kilodollars, it’s nowhere near the most expensive that you can get– these go up into the thousands. The saving grace is that if you don’t actually do critical wiring and don’t need absolute calibration, you can often find these at surplus shops or garage sales (sometimes with old calibration stickers from aircraft companies!), at twenty dollars or under, potentially leaving you with enough cash to pick up the holster.

In the last few years, cheaper “plastic” versionsbased on the same mechanism have become more common as well. It’s nice that such cool tools are no longer unobtainable.

8. Bent-nose mini-pliers. This particular one is from a set of Sears Craftsman Professional mini pliers, but it’s also available separately. Much like the bent-nose tweezers, these let you reach things that you can’t otherwise. They’re handy for positioning components or for forming stiff wires or component leads.

9. Erem flush clippers. For basic wire and component lead clipping, you can do a lot worse than the flush clippers that come in that Sears mini-plier set that we just mentioned. But, these swiss-precision clippers from Erem are about as nice as they come. ‘Nuff said.

10. “Free agent” helping hands. We’re big fans of the usual soldering “helping hands“, but here’s an independent version that you can make yourself. Good for places where that heavy base on the helping hands isn’t helpful, and this one is light and easy to fit in your to-go solder kit. Make it yourself with a few inches of thick solid copper wire and a couple of alligator clips.

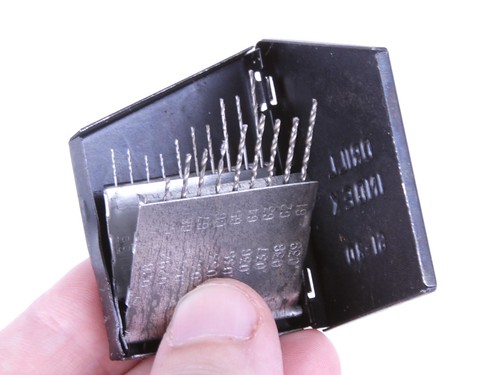

11. The #61-80 drill index. A set of tiny drill bits, ranging from 0.0135″ diameter to 0.039″ diameter. For light-duty drilling of circuit boards, tiny mounting holes, and all kinds of other things that you never thought of. A good adjunct to your regular-size drill set, whatever that size is. Under the microscope each one looks like a full size drill bit; they’re just smaller. And they come in a classic drill index case. That’s good, because at this size they generally aren’t stamped with the size.

You can get these at most places that sell machine tools, but you can get a good deal on them at Electronic goldmine.

Dental tools! I’ve got a small selection that I use as soldering aids. Fine point, high grade steel, they really can’t be beat. Many dentists will give away worn, bent or broken tools for the asking.

Ideal sells different versions for stranded and solid wire. Unfortunately, it’s sometimes hard to tell which model is for which – even by looking at their web site.

That said, Ideal wire strippers rock. I have several, and my father had one as far back as I can remember.

Could you tell me whether the wire stripper you list works with solid core wires ? All strippers that I’ve tested works with stranded but are particularly messy with solid core wires.

I’ve used the listed wire stripper with 14ga romex and it works fine.

You need to pick the right hole to use, but yes, they work like a charm.

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Lots of great tools there (cable tie gun is just beautiful). One thing I’d like to add to the scissor tools is something called Thread Nippers. They are a big time saver when you need to make many small cuts since you don’t have to fit fingers through the handles of normal scissors. Just pick up and snip.

Yep, got two T Strippers, and for flush cutters – Lindström (Sweden).

We used to cal the zip-tie gun a "Duit To-it" since the zip-ties we used were all made by Panduit.

Not strictly an electronic tool, but I find keeping a small brush handy helps. If you are drilling something or cutting/scraping something, a small brush can help move debris out of the way if you don’t want to blow it across your workspace (and in my case, into my keyboard where it will no doubt get stuck). As a bonus it also helps for cleaning out enclosures or old boards.

The wire strippers sold by Sparkfun are actually quite nice, and a steal at just $5. I bought them on a whim because I was having trouble finding and justifying the price of the T-strippers (which I have the pleasure of using at work). I was pleasantly surprised by the quality, enough so that I don’t find myself lusting after the T-strippers any more.

Link: http://www.sparkfun.com/commerce/product_info.php?products_id=8696

Do you have a recommended general purpose crimper, perhaps one that would work well with servo-type JST connectors and their pins?

http://www.very-clever.com/information/xbddddexsxbxdxi

I used a pair similar to this when crimping the leads on heater elements. The connectors had to be heat resistant and they were much tougher then regular connectors coated with insulation. The connectors laughed at the cheap all-in-one tools.

Locking forceps are terrific tools for pulling out old components, like leaky paper caps in old tube amps.

After you’ve sucked as much solder away as possible, lock the forceps on the lead close to the PC board or other solder point such as a tube socket. A little heat and a wiggle and the lead comes out easily. I find the bent forceps are best as they provide some leverage.

They also work well for bending leads into shape on handwired circuits.

I never see anyone suggest Adel Nibblers

http://www.adelnibbler.com/

Really a must for someone who works with sheet metal enclosures and no better way to make a square or rectangular hole.

I like them so much I bought two

Once you get to be 45 or 50 years old and start losing the ability to focus your eyes, a pair of $6 drug store reading glasses should appear in your toolbox. Get the largest diopter they have — you probably want them stronger than you would use to read, because electronic components are typically smaller than type. And get the loudest, ugliest frames you can find, so you can more easily find them in the cluttered blur of your worktable, and to give your spouse a giggle when s/he sees you wearing them.

Don’t forget an ESD safe portable vacuum pick-up tool.

That was in our prior round up; we’re not forgetting. :)

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

I’d like to point out MicroMark as a source for some of the tools. They regularly have the micro-sized drill bits, pliers and nippers, and an array of hobby knife sets, for instance.

Another tool that makes the “essential” list for a maker IMNSHO:

Calipers. These range from the cheaper slide rule style to the more expensive digital output version.

Working in electronics when I was in the service, I used a pair of needle-nose pliers that had wire cutters at the tip of the pliers. These pliers were quite handy, I have been unable to find a pair of them since becoming a civilian. If anyone knows of a source for these pliers, I would be grateful for the link or phone number.

Try Jensen Tools. They have several models from different manufacturers.

One point on the cable tie installation tool is to watch your tension. I’ve seen more than one technician damage the internal strands in a bundle of wires. In one case, a machine started going into a stop condition whenever a particular door was opened or closed. Turns out the tech had the tension adjusted far too high and several wires under the cable tie were damaged or broken internally, even though the exterior insulation wasn’t damaged.

Probably no one else here old enough to remember wire wrapping as the assembly method which started the computer age, as well as the pre-DIY-PCB hobbyist era, but I still have my hand and power wrap tools, and unwrap bit.

Faster prototyping and fully capable of permanent use. the entire backplanes of most early transistorized computers were done via wire-wrap construction.

Google-image "wire-wrapped backplane" for samples.

Panduit Cable Tie Gun

Most awesome tool ever made. On any project where people use cable ties you need to use this tool for one simple reason. You will not get cut or scratched with the stub of the cable tie that gets left because some one use a pair of diagonal cutters to trim it. Flush cuts work OK if their is enough room but this tool works every time.

If you have ever reached into a chassis and had your arm torn open by the sharp stub of a cable tie you know what I mean.

Cable lacing is nice because you never get a sharp edge but i thin it is a lost art since the advent of cable ties.

Windell did you ever work on aircraft? The only guys I know who have ever seen and appreciate this tool have been Military trained or A&P Mechanics.

No, no aircraft experience. But it’s something that I learned to use in a lab, and it’s definitely one of my favorites. :)

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

They are used extensively in the HVAC industry for attaching flex duct to metal duct. Every sheet metal worker knows what this tool is.

I think your scale reads to 0.1g, not 0.01g. I’m shopping for one myself, thank you for posting about this!

>I think your scale reads to 0.1g, not 0.01g

Please zoom in on the picture and see for yourself. The scale is labeled "Max. 200g D= 0.01g," and the reading on the scale, as pictured, is currently 0.00g.

You definitely can get 0.1 g scales, but this precision is very helpful for tiny components.

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Windell – My mistake. The eBay auction I was looking at misquoted the accuracy, and I failed to notice the tiny numbers on the photo. Sorry!

Actually, it looks like there are a few different "SF-700" scales on eBay, with various weight capacities and resolutions. Yikes.