When we recently asked the question, “Does solder expire?” you gave us some excellent answers. Many commenters had a story similar to haineux’s (sometimes replacing 1960’s with 70’s, 80’s or 90’s):

Just recently used up a spool of my father’s early-1960?s-era solder from Lafayette Radio Electronics, and now I’m working on a later-60?s spool labeled “Archer” (a Radio Shack house brand).

There might be some reason new solder is better for something, but I’ve not had any troubles doing standard PCB and parts soldering.

Steve had a great story about learning to solder with a roll of 1/8? flux core solder:

The last time it had been used (~20 years previous) it hadn’t been sealed — the flux core was open to the air. About a foot of it had dried up and evaporated. I didn’t know what I was doing so I didn’t notice at the time, but kept cursing because the solder wouldn’t stick to anything. Eventually I used the roll down to where the good solder lived and it started to flow properly, but it was a frustrating way to learn to solder. The outside of the solder was pretty corroded, a fuzzy matte gray, but it heated and flowed like anything else with fresher rosin.

To this day, whenever I solder with larger gauge solder I make sure the tip of the solder tube is closed before putting it away. I figure it will be good for another 20+ years that way.

Brad had a slightly different perspective:

Old solder might be perfectly “usable,” but try using a 10 year old spool and a brand new spool one after the other on a small-pitch SMD part, and tell me that there isn’t a big difference!

After noticing this for the first time, I never buy more solder than I can use in a couple years.

Paul reflected on different applications having different requirements:

At work we are required to throw out “expired” solder and solder paste. It is a liability problem, the FAA hates to find expired chemicals and uncalibrated equipment on their inspections.

At home I have used twenty year old rolls. My stuff at home is just for my use and no ones life is at risk.

So the general consensus seems to be that rosin core solder will work nearly indefinitely so long as the rosin isn’t affected by storage conditions. Even then, as long as the bad section is removed, the rest will work fine. A few connoisseurs prefer newer solder (especially for small parts), and industrial applications may require strict adherence to expiration dates, but many of the rest of us will continue to use our (long) expired solder until it’s gone.

I am a notorious collector of references and this whole conversation is a good one!

I think this is an entirely different question depending on what kind of parts you are talking about. People who insist on an absolute answer that old solder is just fine or unusable probably only solder through-hole or tiny smd respectively.

I’ve only recently began soldering surface mount components but I have already learned that solder quality makes a huge difference! I wouldn’t even think about using one of those decades old rolls for that, not that those rolls would have been all that great for the job even when new (too thick).

However, through hole soldering is much more forgiving. And then there is non-PCB soldering, such as soldering wires to tabs. I think you could use just about anything for that. Maybe you could melt down some tin foil and old fishing sinkers. :-)

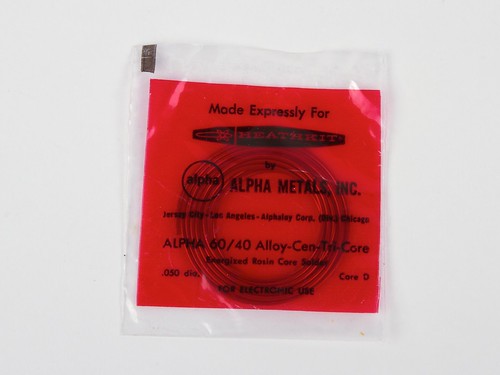

The original article was about an old Heathkit tube-based project. Those pads and leads were much bigger than even through hole parts normally are these days. I suspect that even if one’s life did depend on the product just about any solder would do fine. The only problem I could imagine would be if the rosin was gone however you could always just get some soldering paste and brush that on as you go!

Just as a note, the original question was inspired by comments about two different projects, one of which was a vintage Heathkit project, and the other a modern SMD project.

I wonder if modern, lead-free, RoHS solder expires sooner than “good ol’ 60/40”?

That would seem to be a more important question.

And, of course, the obvious question: Is there any lead-poisoning risk to using lead-based solder? I promise to wash my hands and stop chewing the solder.