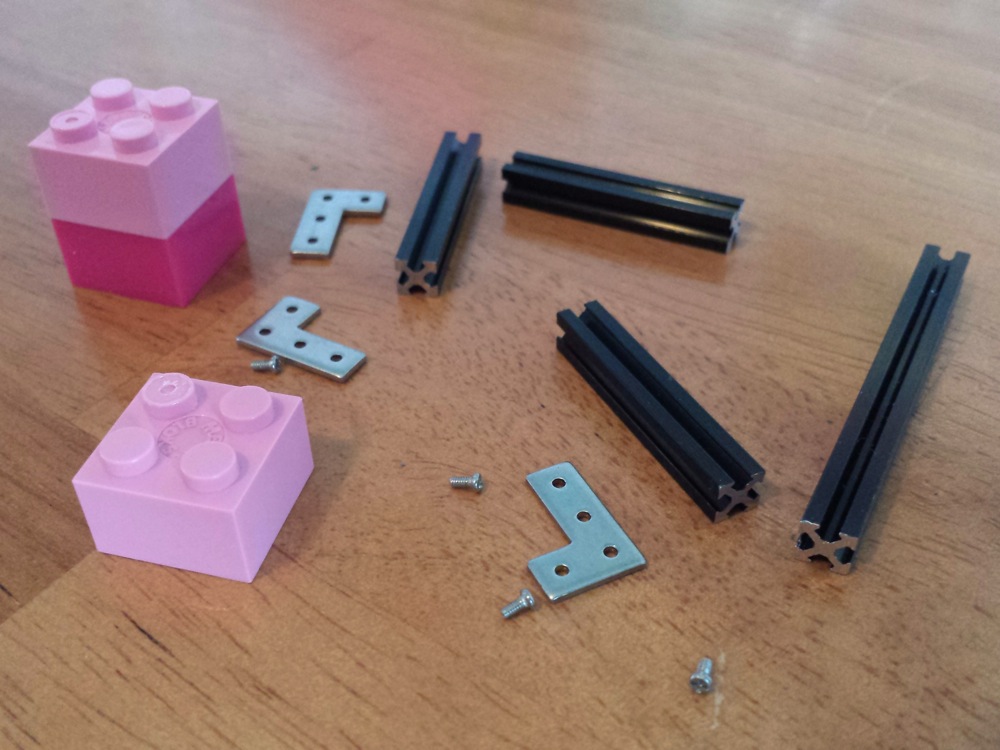

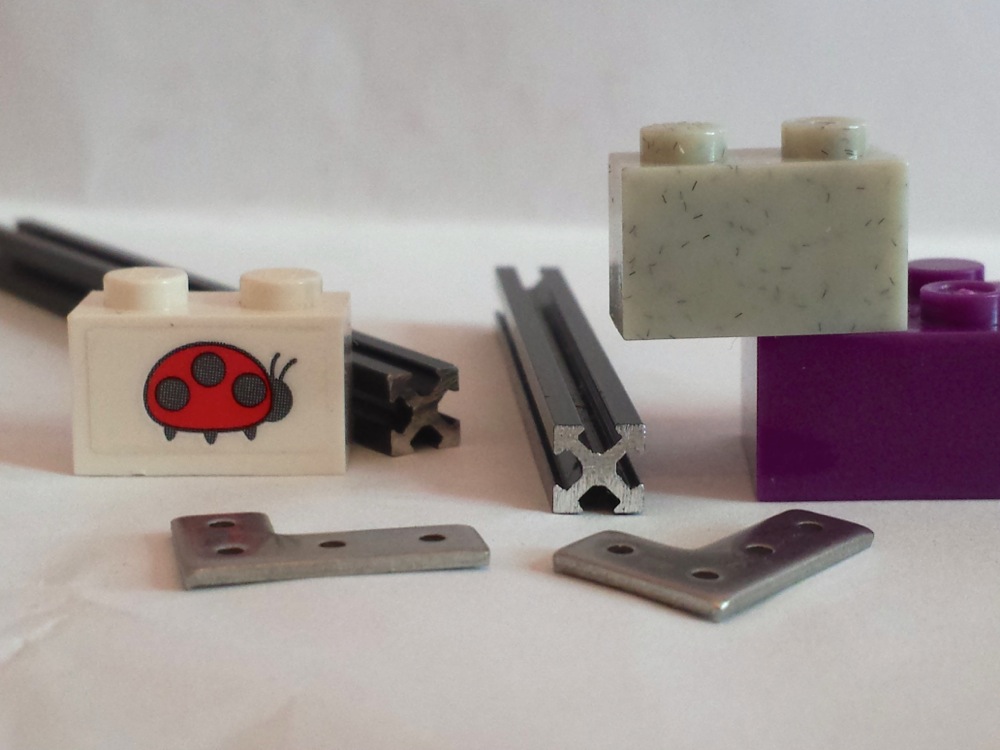

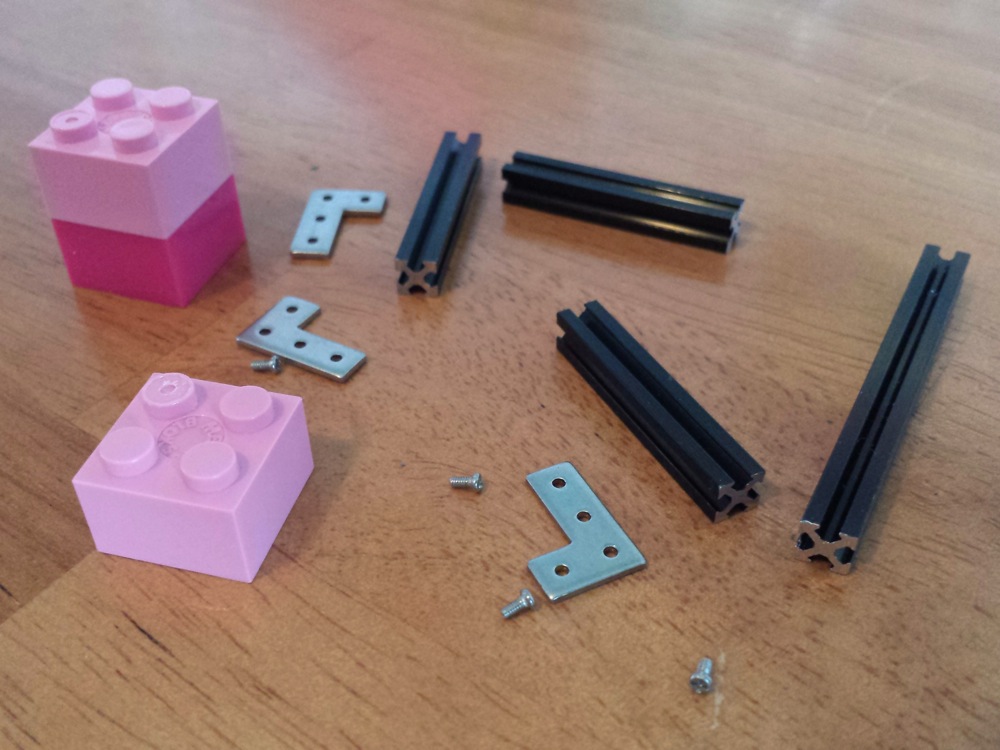

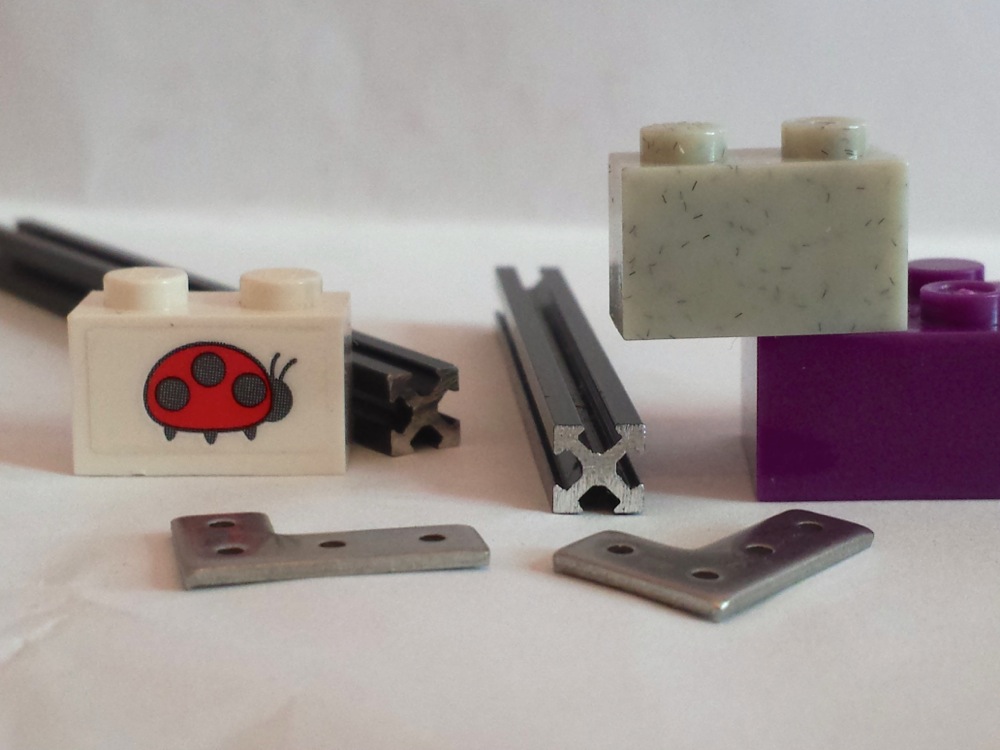

When we saw NanoBeam on Kickstarter, we had a hard time comprehending just how small it is. So we asked Hyrum if he could send us some pictures for a better sense of scale, and he obliged. Yes, it fits in a tic-tac box. After seeing just how teeny-tiny a 5 mm beam is (one quarter the cross sectional area of Maker Beam and one ninth of Open Beam), our next question was “What the heck?” So we asked what made him think of making such a tiny beam.

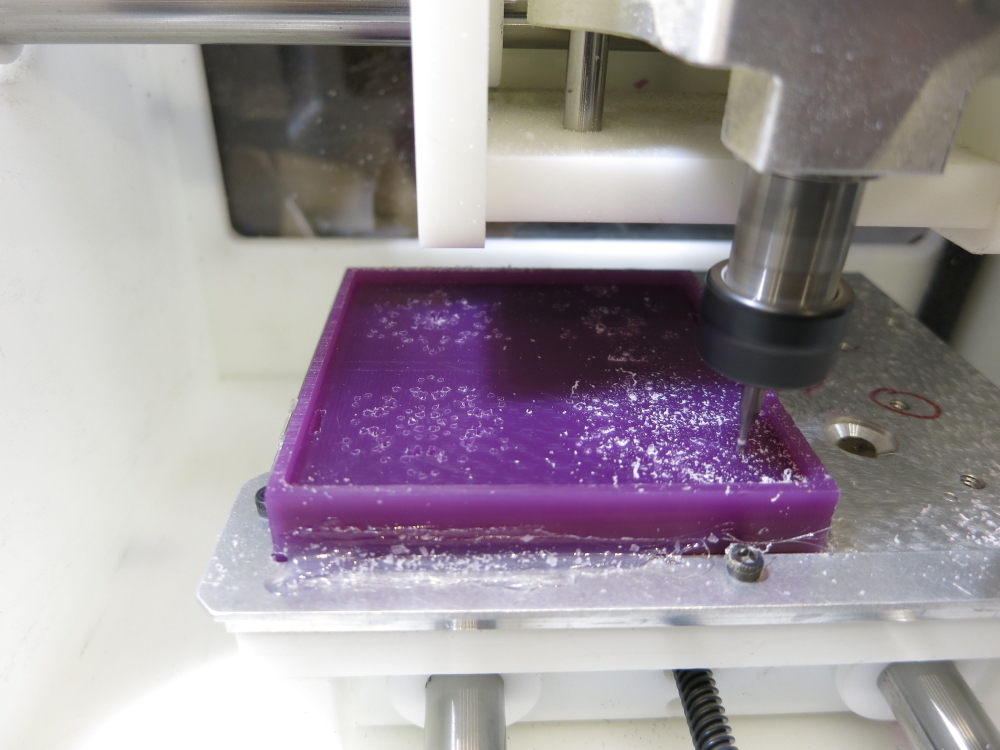

I just wanted some tiny beams to build a small robot. I looked all over the place but couldn’t find what I wanted. After some research, and talking to some extruding companies, I designed a beam that was so small it challenged all the rules of this manufacturing science. I made a few on my cnc mill before I commissioned the die, to be sure it was what I wanted.

How did you find a factory to work with?

I combed the web and talked to a lot of companies. I finally found one that focused on small extrusions. I saw the amazingly small and precise work they were doing for companies like Boeing and 3M and I knew I found the company I needed.

What kind of fasteners do you use for something this small?

I used the largest screw I could but they are still small. The size is M1.2; you will find these in some pairs of glasses. I’ve got 3 designs for the nuts, I am waiting on manufacturing samples for the last one before I decide for sure which I will use.

We asked what he thought NanoBeam would be useful for.

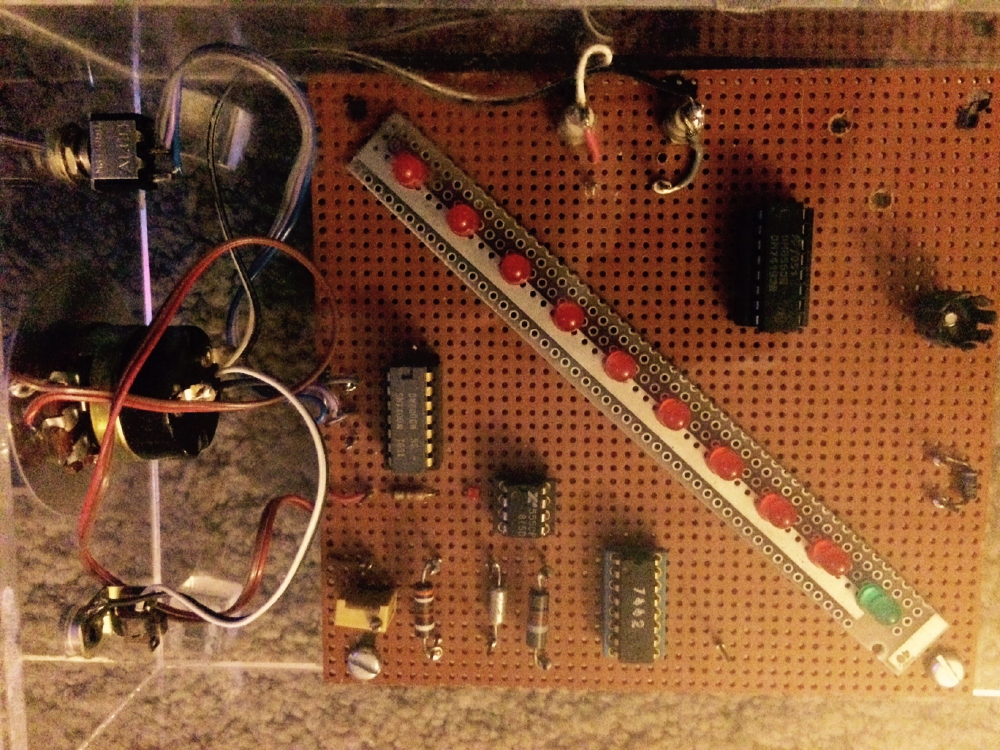

Immediately, I see this making a splash with small robots, quad copters and electronic enclosures. I also see it being great for diy wearables, scale models and crafts. I recently got feedback from a guy that wanted to use them as a frame, conductor and heat sink for an LED array. I can’t wait to see something like that. I’m going to get some stock without the black coating for this application.

We’re also very interested to see what people do with such a tiny extrusion! Thanks to Hyrum for answering our questions. You can find out more, and check out his designs (Open Source Hardware definition compliant) at the NanoBeam website and the Kickstarter campaign page.