While in the course of a recent project, we ended up needing a machine to perform a particular operation. The operation was one that falls squarely into the (rather narrow) set of things that you would expect a “Dremel drill press” to be ideal for. And so (1) we got one, (2) found that it wasn’t very good and then (3) found an excellent alternative: The Drill Press Plus by Vanda-Lay Industries.

All posts by Windell Oskay

Decorating Christmas Ornaments with the Eggbot

Despite what you might guess from the name, our Egg-Bot kit is not just for eggs. In fact, it turns out to be a pretty freaking amazing machine for decorating and personalizing your own Christmas ornaments!

Today we’re releasing the “Eggbot Holiday Super Pak” — a set of Eggbot-ready holiday ornament designs to give you a head start. The set includes the designs above and many more. It’s free, available for download as part of our EggBot Example set (on our GitHub releases page), and will be periodically updated as we add more designs.

Read on for some additional tips and tricks for using ornaments in the Eggbot!

Continue reading Decorating Christmas Ornaments with the Eggbot

Lego Space

No Starch Press was kind enough to send us a review copy of their new book, LEGO Space: Building the Future, by Peter Reid and Tim Goddard. It’s a story book, a gallery book, and a building book, full of all-new space-themed LEGO models, big and small.

WaterColorBot Software and Documentation

We’re wrapping up this week’s updates on the WaterColorBot project with some notes about software and documentation.

Documentation

Our guides for setting up and using the WaterColorBot are already extensive, and still growing. You can find them at the Evil Mad Scientist wiki, or get there with a shortcut: watercolorbot.com/docs.

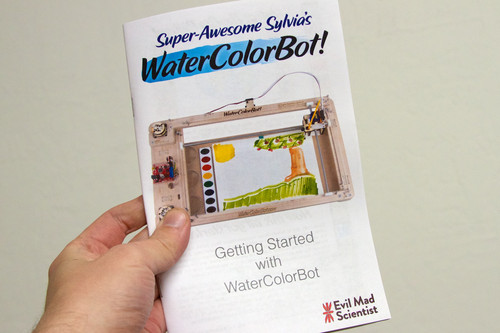

Getting Started with WaterColorBot

One of the most important parts of the WaterColorBot’s documentation is our booklet “Getting Started with WaterColorBot.” The booklet covers the process of assembling the WaterColorBot kit, basic usage, an overview of software options, and a host of tips and tricks. It’s available on our documentation site in PDF format.

Assembly video

We’ve put together a setup video, walking through the steps of putting together the WaterColorBot kit. The video is strictly optional, and covers much of the same ground that the booklet does. You can watch it at http://watercolorbot.com/setup.html, or find it linked from our documentation page.

Software

There are, at present, three primary applications that you can use to control the WaterColorBot, each of which has unique advantages.

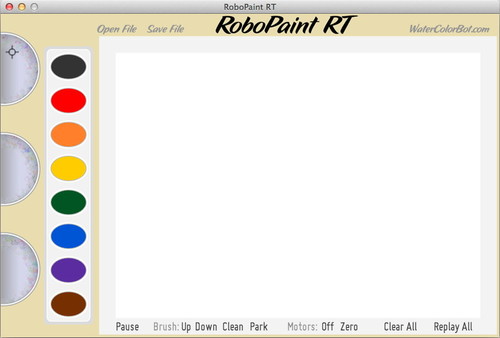

RoboPaint RT

The simplest of the three programs is RoboPaint RT, which is the one that we featured in our Kickstarter video. RoboPaint RT is a “real time” application that allows you to paint with the WaterColorBot. It’s straightforward and manual: Click on a color in the paint palette to change to that color, click on the water to dip the brush in the water, and drag the brush to paint on your paper.

With RoboPaint RT, you can also replay your drawing to make multiple copies, and save the file to open up and print again later. This program can be a lot of fun to play with and is a great way to get acquainted with the WaterColorBot. For those with good artistic skill, it can also be a remarkably powerful program.

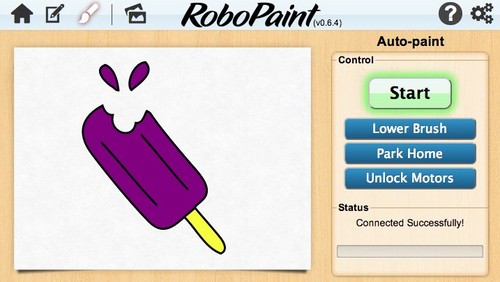

RoboPaint

Next up is RoboPaint, another stand-alone application written by the WaterColorBot team. In RoboPaint, you can open existing artwork in SVG format, snap the colors to your paint palette, and paint the document. It also has a rudimentary edit mode that lets you create new drawings to print. If you’re starting with existing SVG artwork, RoboPaint is generally the best of the three programs to use for a few different reasons. Most importantly, it’s good at automatically filling in large solid regions of a painting.

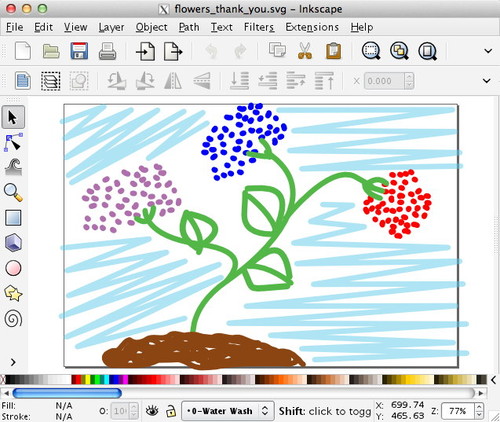

Inkscape, with extensions

The third primary application is Inkscape, a superb, free vector graphics editor, for which we have written an extension (a plugin) to control the WaterColorBot. Our extension provides fine grain control over exactly what will be painted, but more-or-less requires that you create the artwork within Inkscape to take full advantage of the features.

Above, the drawing used to make the Robo-painted thank you cards that we wrote about earlier this week.

Inkscape is also capable of importing artwork in PDF format (as well as tracing bitmap graphics to some extent), and saving as SVG graphics that can be used with RoboPaint. If you’ve ever used an Eggbot (and its Inkscape based driver) you might want to start here, before trying the other apps.

And if you like to code…

For developers (and people who just like to tinker with code), there are additional options:

– Rolling your own, starting with our examples. RoboPaint RT is written in Java/Processing, RoboPaint is written in JavaScript, and the Inkscape extensions are written in Python. These can provide a nice starting place, in a few different environments.

– Direct serial control. The “EBB” motor controller board used on the WaterColorBot can be independently controlled from any environment that can send serial data to your USB ports. Its command set documentation is here.

– The RESTful API. RoboPaint includes the “CNCserver” API for WaterColorBot, documented here. You can use this interface to control the robot locally (from your computer) or remotely (from anywhere on the internet, if you enable the remote option within RoboPaint and tell the other computer what your IP address is). Currently this is a low-level API; we are working on a higher level version where you can simply send an SVG file for RoboPaint to process and paint.

WaterColorBot kits are shipping now, and we are still taking pre-orders for December shipment.

The Making of the WaterColorBot

What goes into making a WaterColorBot? A lot, it turns out.

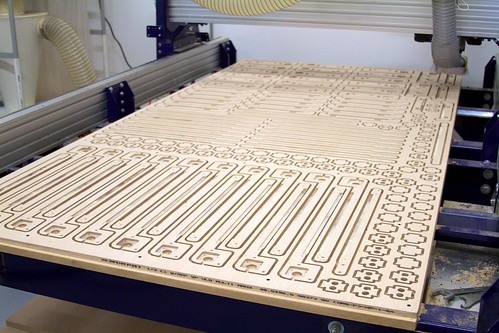

It all starts with a 4×8 foot sheet of Oregon-made maple-faced hardwood plywood. We mount the sheet on CNC router for a process that involves five tools (ranging from 0.086″ to .375″ in diameter) and about 2 1/2 hours of cutting time. We can fit 20 WaterColorBot frames, complete with their feet, on a single sheet of wood — efficiently tiled with very little waste. It’s also time efficient: Just under 8 minutes per frame.

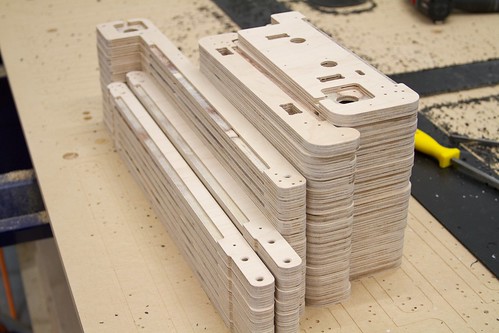

The parts are held into the sheet by little tabs, so that they don’t go flying out during the machining process. We chisel them out of the sheet and inspect them prior to sanding. At this point the parts are carefully shaped and detailed but still rough to the touch around the edges.

Next up, sanding. Sanding removes the tabs and smooths the edges and surfaces to the touch. We use a combination of belt, disc, handheld power sander, and hand sanding for the various surfaces. All told, sanding all of the parts takes a little more than than twice as long as it does to cut them out of the sheet. (That might sound backwards until you watch how fast a CNC router moves compared to a human operating a sander.)

After sanding, the parts are clean and smooth, ready for engraving.

A special jig holds the four frame pieces in the laser for engraving. There are two passes, one for the primary markings, and one for the defocussed (blurry, dark) “WaterColorBot!” title text. We also engrave the back side of the top pieces (with a separate jig) with credits and the serial number.

Stacks and stacks of WaterColorBot frame parts, before and after engraving.

The surfaces of the WaterColorBot are covered with a number of stainless steel rivets — either bare or with a ball bearing –that guide the Spectra cord around the frame as pulleys. We individually press-fit them into place with a small 1/2 ton arbor press.

The arrays of the four frame pieces– CNC cut, sanded, laser-engraved, and with their rivets press-fit — are now ready for assembly.

We use another specialized jig to hold the four frame pieces rigidly in place while screwing them together with a torque-limited electric screwdriver.

There are two types of “feet” that get mounted to the frame. The two left feet (always a fun term to use!) have holes in them to route the motor wires, while the two right feet do not. The feet are attached with wood glue, with the help of (yet) another specialized jig.

After that, we mount the back-side cable guide support, and queue the frames up for having their motors attached and final inspection.

The lower-deck pieces (“spoilboards”) are cut from 3/8″ MDF on the CNC router, in a much, much simpler process. They too are sanded and laser engraved, prior to having their paper clips mounted and being queued for inspection and shipping.

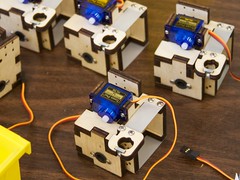

Next up: The WaterColorBot carriage. The base of the carriage consists of six pieces of laser-cut 1/4″ plywood. We found a very fast process of attaching these together, which is to clamp the box together with two perpendicular sets of thumbscrews and thumb-nuts (color coded as you see), and to wick in cyanoacrylate (super glue) between the surfaces at a few key points. It takes only a minute to assemble one; much faster than we were able to do with fasteners or wood glue.

After mechanically drilling pilot holes to mount the servo motor, we assemble the rest of the carriage: Four bushings, two flexures that form the vertical linear stage, the servo motor, and the brush holder.

And then finally the 36″ servo extension cable and a laser-cut delrin cable guide, that prevents the cable from dragging on the paper. All neat and tidy.

The winch is also assembled from laser-cut wooden parts. The lower part has the shaft collar that mounts to the motor shaft, and the upper part has two halves that disassemble for cord management. It turns out that the winding-drum part of the winch needs to be quite round and concentric with the motor shaft for smooth operation– smoother than we can get with the laser. We solve this with our very-most-complicated assembly jig, which we’ll write about separately, if there’s interest.

In the kit, the winches come pre-wound with the appropriate length of 100 pound Spectra cord. We actually use an Eggbot as our tool to wind the cord. We mount the “spool” to one of the Eggbot stepper motors, and spin that motor (very quickly) for a set number of full revolutions to wind a fixed amount of cord onto each winch, using a modified version of the WaterColorBot software. Each winch is wound with about 125 inches of cord, in just nine seconds.

A box full of wound winches, ready to be added to our accessory bags.

The steel shafts that move the carriage came as 3 foot long rods, in a wooden crate the size of a coffin. We sent them to a local machine shop to be cut to length, after which they looked much neater.

We ended up purchasing four hundred sets of Crayola Washable Watercolors. After we received our giant drop shipment from Crayola– which was unreasonably fun, in a grade-school sort of a way –we stacked them all on the table to take a photo.

The paints, along with most of the other WaterColorBot accessories– wound winches, water dropper, velcro straps, power supply, and USB cable –get packed up in a pouch that will go in the shipping box.

Our “getting started” booklets — printed and stapled. (We’ll be talking more about documentation in our next update.)

Our shop cat, Zener, has not actually helped out with production whatsoever. She did, however, manage to get her tail caught in the output roller of our (warm and tall) laser printer a couple of days ago, leading to a little down time while printing those booklets. (Cat is OK, less some fur. The printer is still recovering.)

And then, there’s final inspection. All the parts come together (with a giant checklist) in a padded carrying case with a reinforced handle.

The carrying case has a silkscreened cover. The metallic silver printing ink that we used for the first two batches looks really cool, but becomes invisible at a certain angle. So, we’re switching to an aqua blue for the next batch.

The completed WaterColorBot kits go in an outer shipping box, that keeps the carrying case safe for transport. It’s surprising how much of a warehouse you can fill with stacks of boxes!

WaterColorBot kits are shipping now, and we are still taking pre-orders for December shipment.

Robo-Painted Thank You Cards

One of the rewards from the Kickstarter campaign for our WaterColorBot was a “Robo-Painted” thank-you card. Our collaborator Sylvia designed the cards and supervised while the robot painted them.

We (the humans) were a little tired after just signing the insides of 75 cards— we can only imagine how exhausted the WaterColorBot must have been after painting the fronts and insides! They were actually painted in three passes: for the inside “Thank you” text, for the light-blue (extra-wet) background on the front, and for the flower subject on the front.

Of course, the real magic of robotics is that it is so reproducible, card after card. And yet, the real magic of watercolor as a medium is that it isn’t completely reproducible. Look at the subtle little variations caused by the amount of water either in the light blue background or in the flower subject. We see the same kinds of “organic” variation that we might expect from a human artist. Simply wonderful.

Two New Menorah Kits

Hanukkah comes remarkably early this year, starting on Thanksgiving day, November 28.

Today, just in the nick of time, we are releasing two new LED menorah kits for 2013 that complement our consistently popular Deluxe LED Menorah Soldering Kit.

The first kit, the Deluxe Electronic Breadboard Menorah Kit, is a response to two requests that we frequently receive: (1) for an LED menorah kit that doesn’t require soldering and (2) for a menorah kit with assorted multicolor LEDs— for that assorted-color candle look. (Nailed it!)

The kit includes a 6″ transparent breadboard, 10 mm LEDs in red, orange, yellow, green, blue and warm white, a control button, battery holder, and a pre-programmed microcontroller.

While the electronic components— the microcontroller, resistors, control switch, and LEDs —are essentially the same as in the Deluxe LED Menorah Kit, we’ve had to make quite a few changes to the layout and firmware to redesign the circuit to lay out so neatly on a breadboard. Additionally, as the perceived brightness of different LED colors can vary quite a bit, we’ve included a specific set of per-color resistors to even out the overall brightness levels.

The Deluxe Electronic Breadboard Menorah Kit is in stock now, and ready to make happy campers on some night(s) of Hanukkah this year.

For the second new kit, the multicolor Special Edition Deluxe LED Menorah Kit, we’ve brought the assorted multicolor LEDs back to our original Deluxe LED Menorah Soldering Kit. Because, why should breadboarders have all the fun?

And it even looks good with the lights off! The new Special Edition LED Menorah Kit is in stock and shipping now.

Scary 1040 Tax Return Pumpkin for Halloween?

Mike Pucher writes on twitter:

@EMSL I used my #eggbot to make a pumpkin for my wife who is a CPA. There’s a first time for everything- even this.

Maker Faire NY 2013, Day One, in Pictures

Day one of the 2013 Maker Faire New York was incredible. We’ve nearly lost our voices after speaking with folks about our projects, all day long in the Atmel area of the Make:Electronics tent. However, we tag-teamed a bit and managed to take photos of many of the sights to see– costumes, robots, oodles of 3D printers, handmade furniture, mars rovers, UAVs, underwater ROVs, electronics, and so many other incredible projects. You can see the full photo set here.

We’ll be back for more; Maker Faire continues tomorrow (Sunday) at the New York Hall of Science.

WaterColorBot Goes into Production

This has been a busy and invigorating week at WaterColorBot HQ, as we’ve finalized the hardware design for the WaterColorBot and begun in earnest the manufacturing process.

That term “finalized” carries a lot of weight with us. It marks the end of a seven month period of making regular iterative improvements to the WaterColorBot design. When we launched our Kickstarter campaign back in July, we had thought that we were already done with the process. However, it turned out that having these two extra months between launch and shipping gave us an invaluable opportunity to refine and finesse many of the little details that we had already spent so much time on.

Here are some of the highlights of that process; some subtle yet wonderful little improvements that we’ve made to the WaterColorBot.

An improved brush lift mechanism

Since we started the project, the carriage on the WaterColorBot has been refined through over 30 revisions, including a half dozen or so just since we launched our Kickstarter campaign in July. Some of these revisions have been minor (for example, rounding the corners more to make it more finger friendly, or tweaking the tolerances on the guide bushings).

Other revisions have been more substantial. In the last few revisions, we changed the way that the brush-lift servo motor actually lifts the brush. Previously, the motor directly pushed the brush holder up or down. But there is now a little stainless steel wire form that transmits motion from the motor to the brush holder. By adding it, we’ve made it so that the brush has a full 3/4” (19 mm) of travel– up from 1/2” (12 mm) –making it possible to push the brush down lower to better wash between changing paint colors, and to go up higher, more readily clearing paper and paint.

An improved lower deck

The lower deck of the WaterColorBot, affectionately known as the “spoilboard” is machined from medium-density fiberboard (MDF), with indentations to index the paint set and water dishes, and a clip to hold the paper. In WaterColorBot 1.0, we’ve moved from 1/4” to 3/8” thick MDF, making it tougher, more substantial, and better weighted. We’ve also added new laser-engraved indexing marks that show you where to position other sizes of paper (US letter and A4), in case you’re not using 9×12 watercolor paper.

On a related note, we’ve also been developing an alternative plastic spoilboard as an add-on accessory, which may be helpful for artists who like to paint on soaking-wet paper.

Better bearings, yet again

And finally, one last upgrade to the motion control system. As you may recall, the carriage that holds the brush is moved by cords driven by stepper motors. After upgrading to the Spectra cord last month, we found that we could make a further improvement in the overall performance of the robot by replacing three specific plain-bearing stainless steel pulleys with miniature ball bearings. Those three places are the three locations on the WaterColorBot where the cord is directed in a U-turn (for example, at point ‘E’ above). Without the ball bearings, the friction at those three points can potentially be significant, particularly if the cord is operated under tension. And with the ball bearings, the robot can run faster and smoother, with lower current to the motors.

The WaterColorBot kit is now available for pre-order at the Evil Mad Scientist Shop.