When we recently wrote about looking at solder paste up close, we happened to mention that it has a shelf life— something that you might expect to be uncontroversial considering that there is an expiration date, printed right there on the jar.

But, our reader Trav commented

Very nice pics. What happens to solder paste when it expires? does it taste funny? Do the balls go flat?

I assume the paste rather gets runny and doesn’t hold the solder in place or it gets thick and won’t spread evenly.

I’ve heard of it expiring, but never knew how. I’ve had a tube of flux for 20 years now. When it gets too thick, I put in a couple drops of alcohol and it seems to work good as new.

We like the “balls go flat” theory! But seriously, we presume that they wouldn’t label paste with a short shelf life— typically 4-12 months, when kept refrigerated, depending on the type of paste —unless there were a reason (and hopefully, a good reason) to do so.

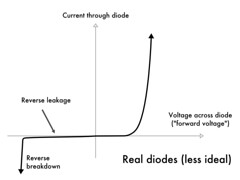

A blog post on the Indium Corporation web site offers a little insight. It turns out that the “activator” chemicals within the flux, which serve to clean oxides off of the surfaces that will be soldered, also interact with the microscopic solder balls, gradually scouring off their surface oxides. When the solder particles are clean enough, they can actually cold-weld together, resulting in increased effective grain size and viscosity. As Trav notes, adding a little alcohol can reduce the viscosity of flux, but we can see how increased grain size and other factors (such as having used up some of the activators) could affect performance in other ways.

But in any case, it sounds like there are a range of experiences out there, and we would like to open the question for discussion: What has your experience been with out-of-date solder paste? Has it worked just fine? And if not, what was the failure mode?

Separately, what about (flux-cored) solder wire?

Kester has this to say, in their policy about shelf life:

Flux cored solder wire has a limited shelf life determined by the alloy used in the wire. For alloys containing more than 70% lead, the shelf life is two years from date of manufacture. Other alloys have a shelf life of three years from date of manufacture.

So, our spool of lead-free solder pictured above, with date of manufacture 3/16/05 expired five years ago in 2008. Presumably one reason for a stated expiration date is that the flux becomes less active over time as it interacts with the solder metal.

But in our personal experience, this kind of solder seems to generally work just fine, even many years past its nominal shelf life.

Many others seem to have had a similar experience with solder wire.

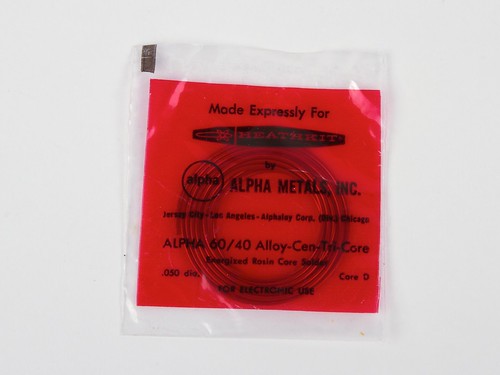

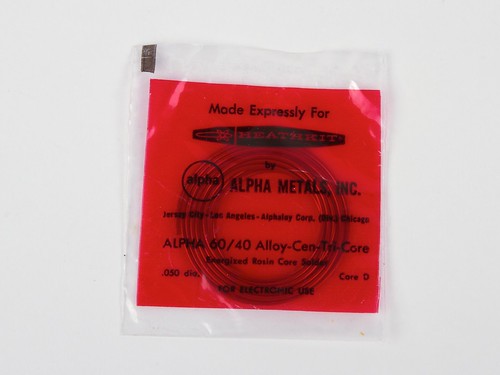

When we wrote about assembling a vintage Heathkit, we mentioned that it came with solder. It actually came with two little packets of solder, specifically 60/40 rosin-core, cheerfully labeled “Made Expressly For Heathkit by Alpha Metals, Inc.”

Seeing as (1) the kit and solder date back nearly 40 years, (2) Alpha Metals also uses the three-year figure for shelf life, and (3) we already had a fresh, open spool of Alpha Metals 60/40 rosin-core solder in the lab, we opted to use the fresh spool and save the vintage solder packets for a rainy day. Were we wrong to do so? Certainly, some of our readers thought so:

Solder shelf life? Are you sure about that? Solder paste has a shelf life but I’ve never heard of a shelf life for a real coil of 60/40 rosin core solder. I’ve used some pretty old stuff myself, a quick Google search for solder shelf life found me a discussion where a guy is talking about using solder from the 60s with no problem on the first click!

So what has your experience been? Have you used “old” solder, and if so, how well did it work?