Leigh Klotz, author of Ham Radio for Arduino and PICAXE, gave us this interesting chip from the 80’s to play with: a UM3482A “Multi Instrument Melody Generator” IC. While not quite rare, it is a bit of a vintage curiosity these days, and we wired one up to see what exactly it does.

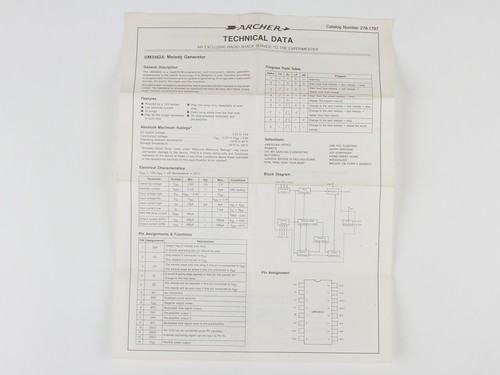

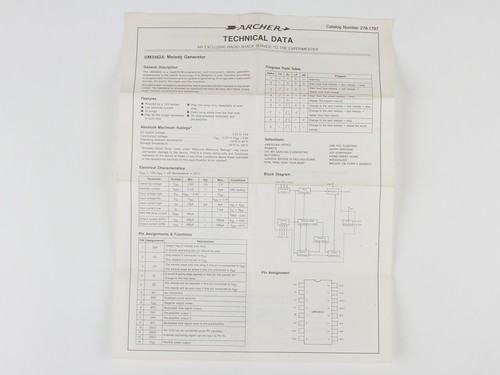

The vintage Radio Shack Archer package it came in was minimalist (though not quite this minimalist as it came to us– imagine that the chip were still there in the bubble). It promises not just 12 tunes, but circuit diagrams as well.

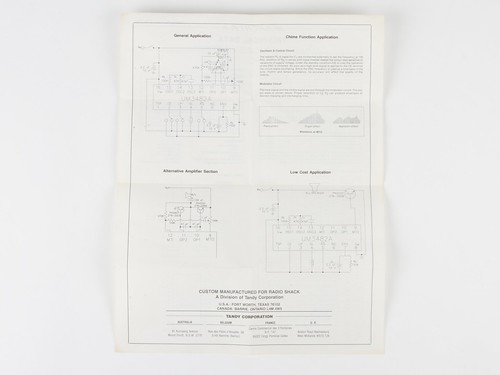

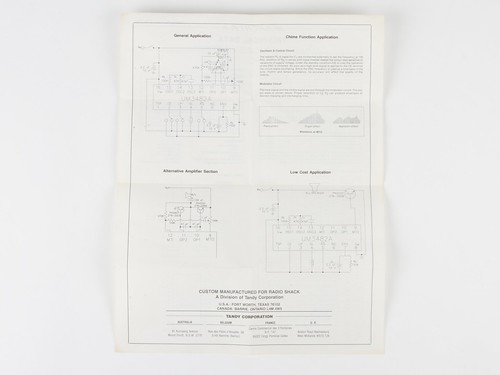

This Archer-branded datasheet (including the promised circuit diagrams) came stapled to the back. You can download a readable copy of the manufacturer’s original datasheet here.

“A mask-ROM-programmed multi-instrument melody generator, implemented in CMOS technology. It is designed to play the melody according to the previously programmed information and is capable of generating 12 songs with 3 different effects: piano, organ, and mandolin.”

Amongst the twelve musical selections are London Bridge, Row Row Row Your Boat, Oh My Darling Clementine, and (of course) Happy Birthday. Suggested applications included toys, door bells, music boxes, and telephones. (File under: Customized ringtones of the 80’s?)

The three little graphs in the upper right show the three different timbres (the “instruments,” in the phrase “multi-instrument”) in terms of amplitude versus time. The other diagrams show how to wire it up to a speaker and how to configure the various inputs to select which song to play and so forth.

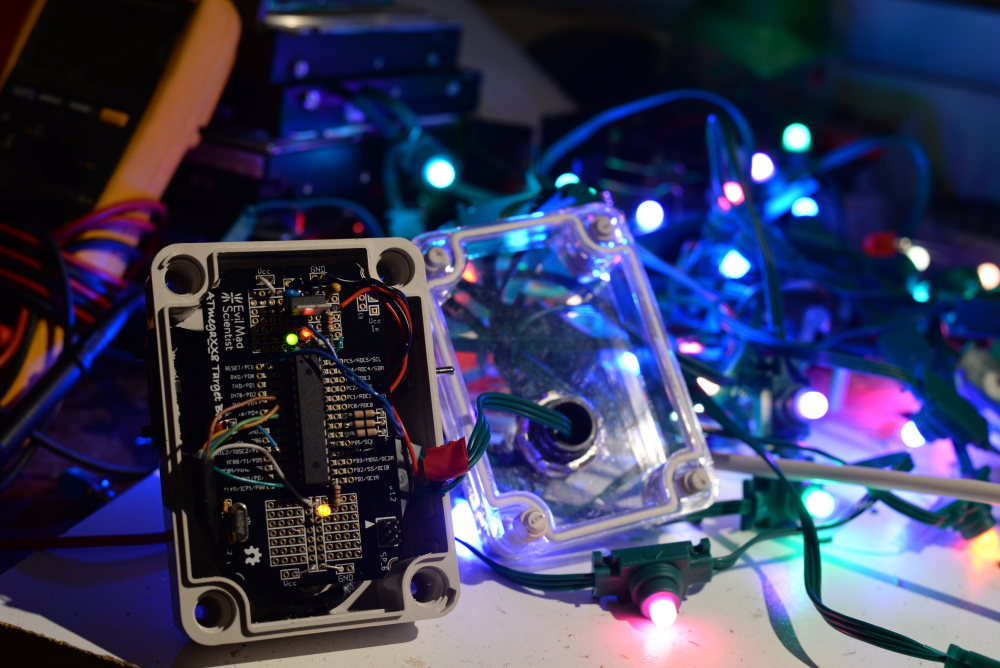

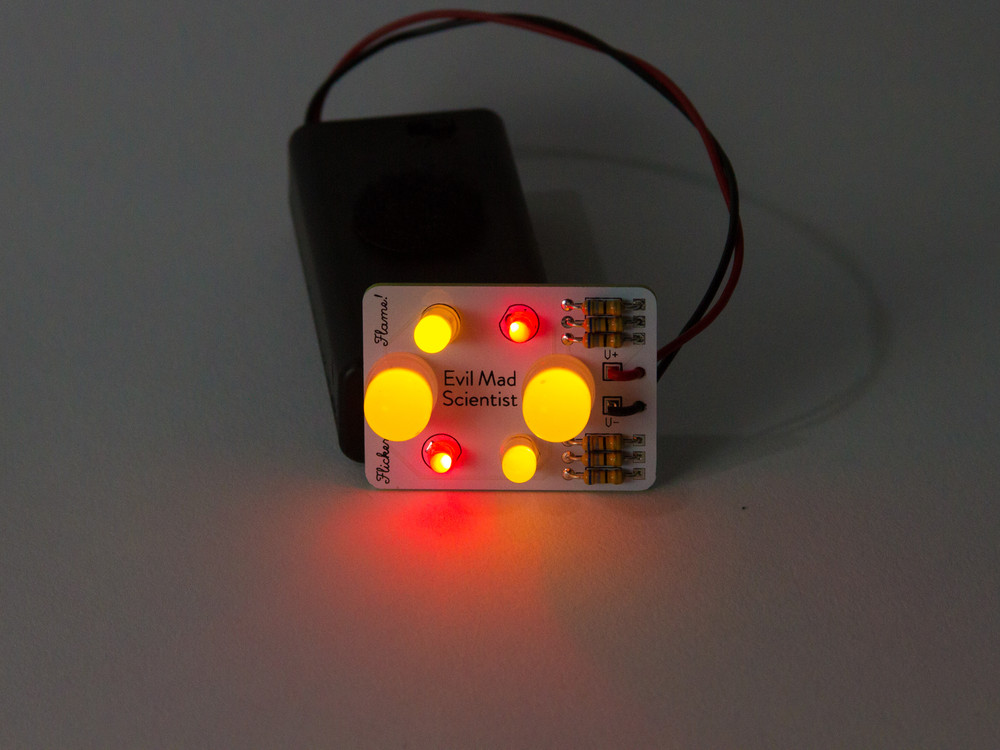

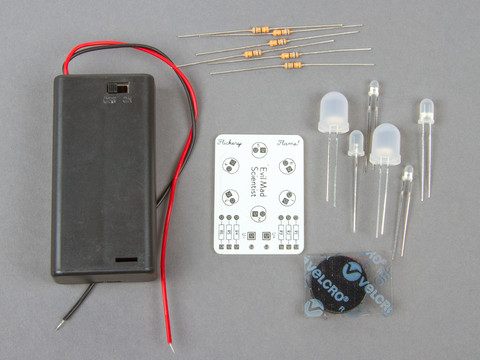

We breadboarded up a sample circuit from the datasheet, substituting with parts we had on hand, including a little magnetic buzzer as the speaker. A 2xAA battery holder is connected up to the power and ground rails. There is a momentary button switch to select the next melody in the set, and a row of DIP switches to set the configuration options.

And sure enough, it plays melodies.