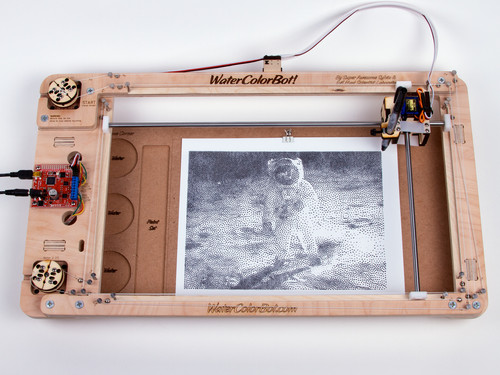

One of the questions that we’ve had on the WaterColorbot is about its ability to use higher-quality materials. And in particular, can you use it with fine (artists’) watercolor paints?

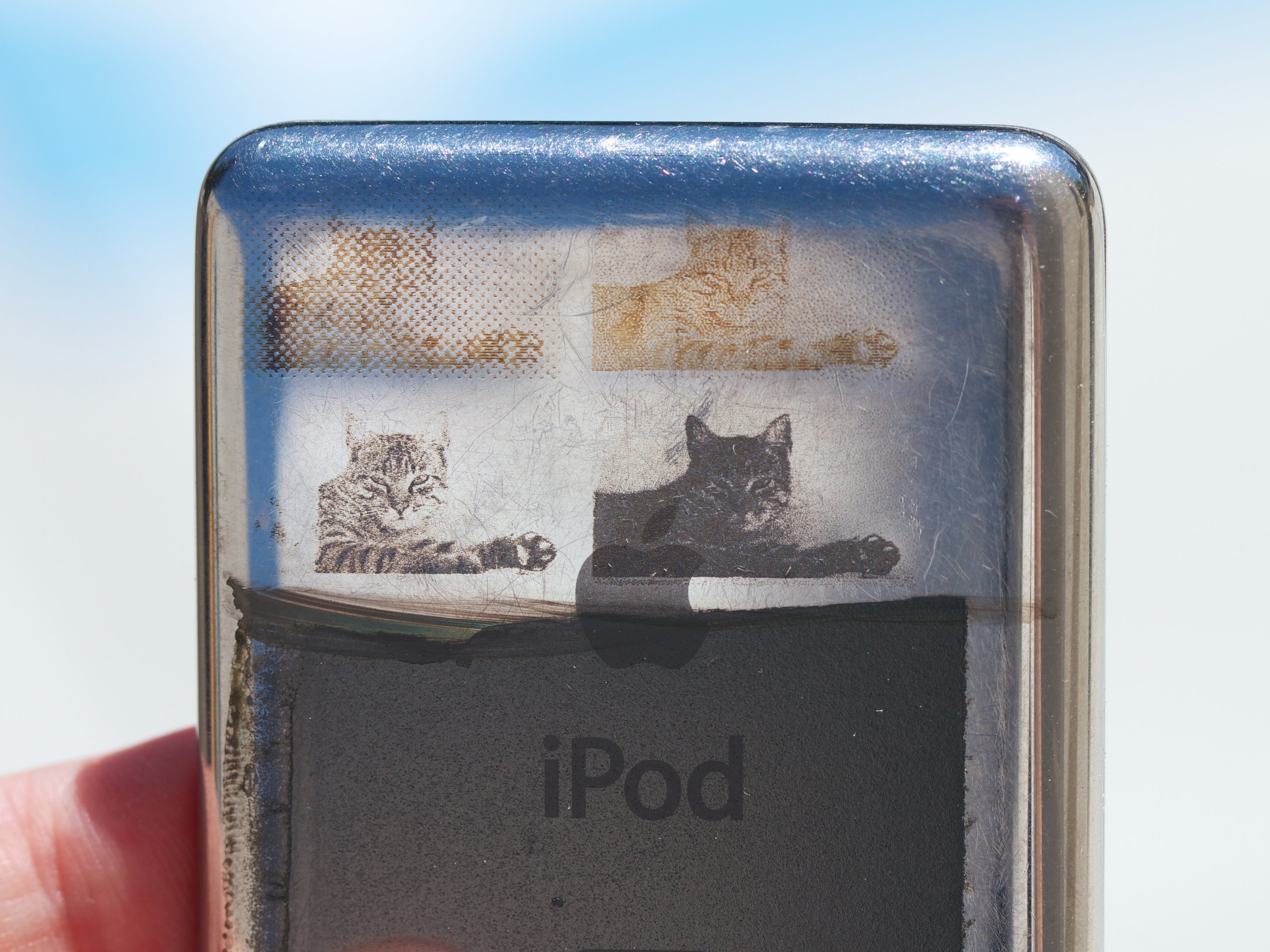

The WaterColorBot comes with a starter set of Crayola watercolors. This kind of paint set is great for kids and great for learning how to use the WaterColorBot. And in the United States at least, it’s also easy to obtain direct replacements from your local office or art supply store.

But on the other hand, watercolors like these do not offer the depth or range of color nor the archival quality that professional artists expect and require. And, replacement paint sets may not be so easy to find overseas, or even in less urban areas of the US. Fortunately, you can use the WaterColorBot with other paints, and we’re working on expanding the number of different ways that you can.

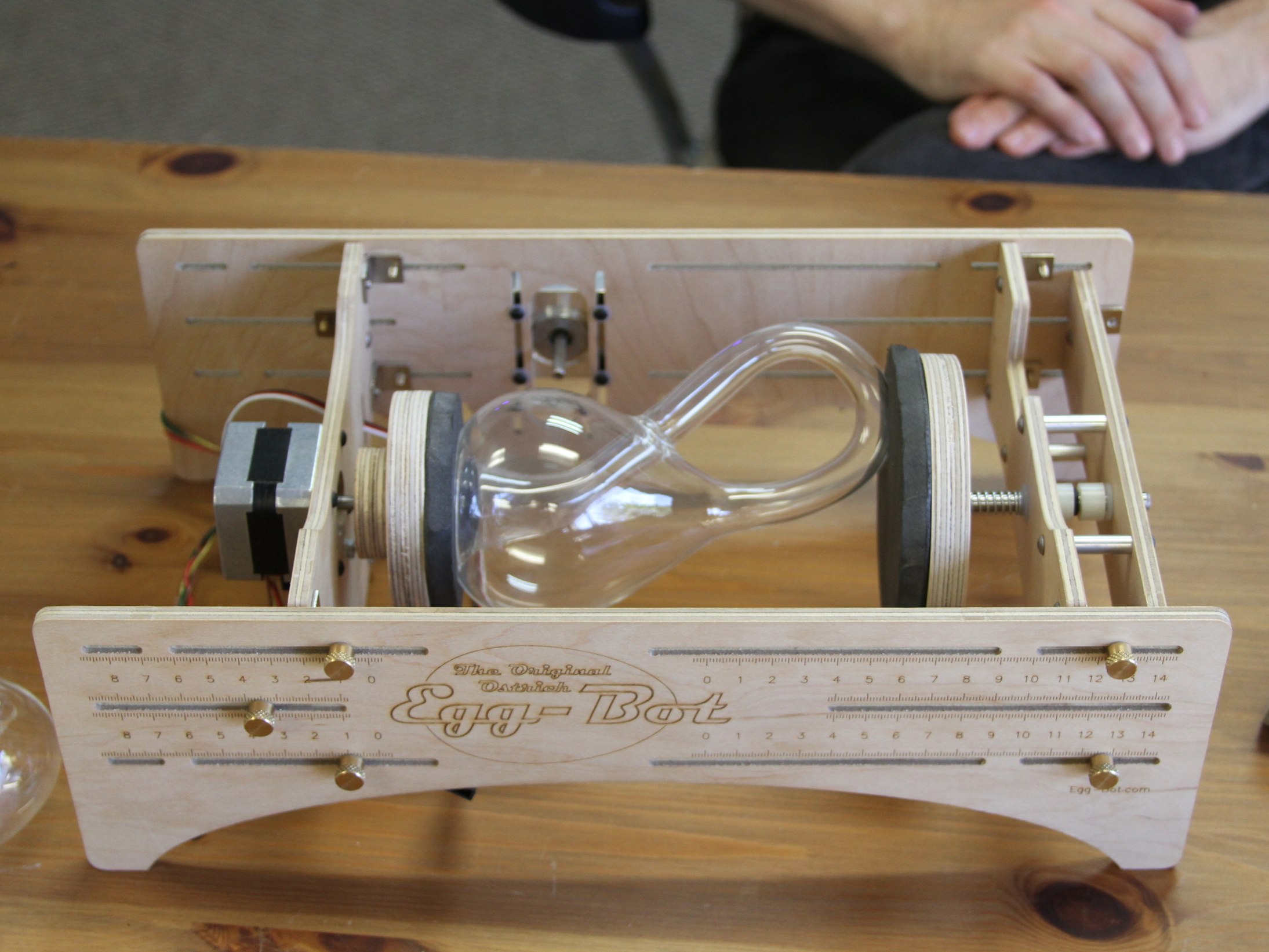

The first, easiest solution is to note that the Crayola paint set actually comes with (well, in) a perfectly-sized paint palette; simply rinse out the remaining paint with cold water.

The empty Crayola palette can be reused with tube-based watercolor paints, which are available at art supply stores worldwide. Like dry (pan) watercolors, tube based watercolors are available in many grades, from very inexpensive to fine artists’ watercolor, and in a truly impressive range of colors.

While the the empty Crayola palette is perfectly serviceable, it is a bit flimsy, and we are also planning to offer a couple of more durable permanent palettes as optional accessories for the WaterColorBot.

Here is the first of those accessories: A milled plastic palette for use with tube-based watercolor paints. It’s tough and permanent with eight oval wells.

For artists who prefer to paint from pans (dry paint), our second accessory is a palette that cradles up to eight “standard” half pans, which are one of the preferred shapes for artists’ watercolors. The word “standard” is in quotation marks because there is actually quite a range of variation in the size of half pans; this particular palette is sized for Winsor & Newton (and Cotman) watercolors. We also plan to offer other holders to fit half pans from other manufacturers.

And what about paper?

The WaterColorBot is designed to fit 9×12” paper, which is one of the most common sizes for watercolor paper. Heavier and finer grades of paper (140 Lb, 300 Lb) can be used without issue, and standard methods for affixing paper to the board– such as tape and tacks –will work just fine. Larger sheets of paper can be cut down to fit, and smaller paper– including A4 and US letter –can be used, although you may need to pay attention to the margins.